Details

Classification and characteristics of heat exchangers

- Categories:Knowledge sharing

- Author:

- Origin:

- Time of issue:2021-11-05 09:59

- Views:

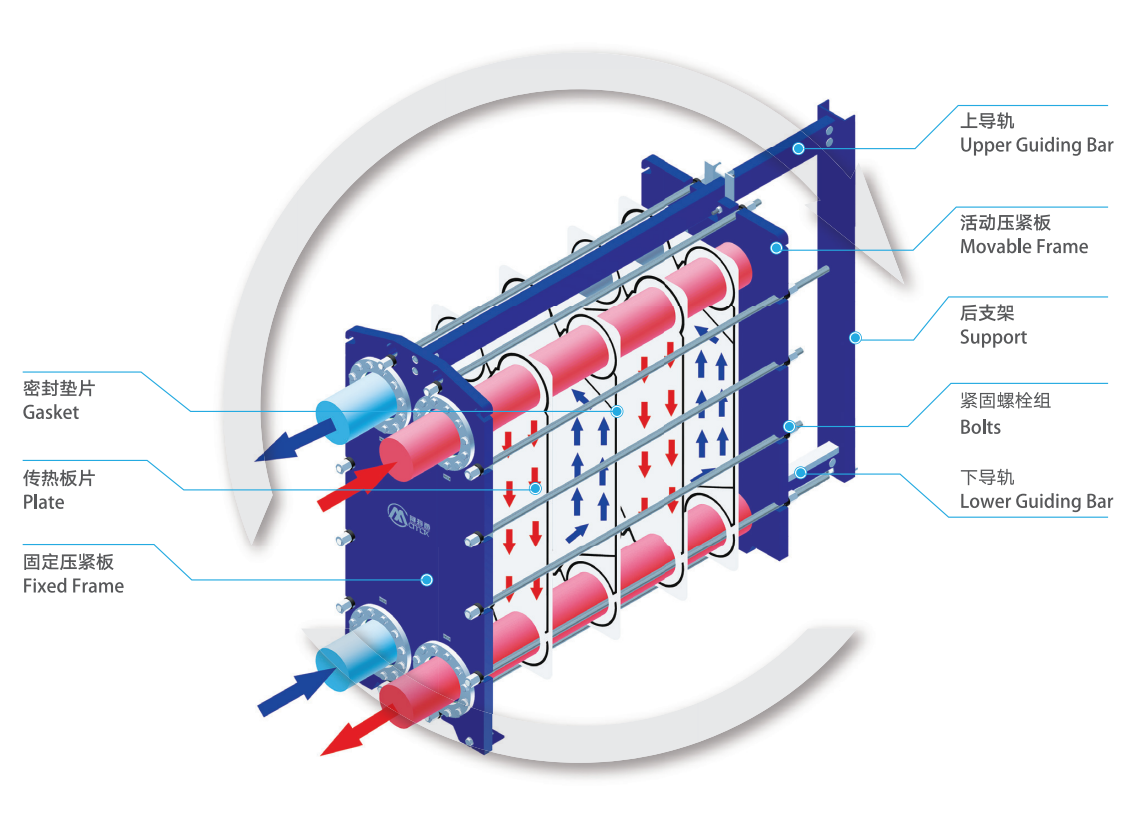

(Summary description)The dividing wall heat exchanger is the most common in the heat exchanger market. Its main principle is to effectively separate multiple fluids at different temperatures to ensure that it can flow quickly in the dividing wall space. And using the interface function, through the heat conduction and convection methods, it is realized that a variety of different temperature fluids can complete heat exchange under certain conditions. The main structural forms of the partition wall heat exchanger mainly include jacket type, spray type, immersion type, plate type and shell-and-tube type. It is very extensive in terms of market sales and applications, and is currently the most widely used heat exchanger.

Classification and characteristics of heat exchangers

(Summary description)The dividing wall heat exchanger is the most common in the heat exchanger market. Its main principle is to effectively separate multiple fluids at different temperatures to ensure that it can flow quickly in the dividing wall space. And using the interface function, through the heat conduction and convection methods, it is realized that a variety of different temperature fluids can complete heat exchange under certain conditions. The main structural forms of the partition wall heat exchanger mainly include jacket type, spray type, immersion type, plate type and shell-and-tube type. It is very extensive in terms of market sales and applications, and is currently the most widely used heat exchanger.

- Categories:Knowledge sharing

- Author:

- Origin:

- Time of issue:2021-11-05 09:59

- Views:

The dividing wall heat exchanger is the most common in the heat exchanger market. Its main principle is to effectively separate multiple fluids at different temperatures to ensure that it can flow quickly in the dividing wall space. And using the interface function, through the heat conduction and convection methods, it is realized that a variety of different temperature fluids can complete heat exchange under certain conditions. The main structural forms of the partition wall heat exchanger mainly include jacket type, spray type, immersion type, plate type and shell-and-tube type. It is very extensive in terms of market sales and applications, and is currently the most widely used heat exchanger.

Regenerative heat exchange is mainly based on energy storage, and the energy storage effect is improved by means of fillers. Quickly transfer energy, that is, work from a certain fluid at the moment and transfer it to another fluid. The heat storage body is mainly composed of solid material organization. The heat in the heat storage body is effectively transferred to the low-temperature fluid. The sequence is that the heat medium first transfers its heat to the heat storage body, and then the cold medium generates heat after fusion with the heat storage body [2]. And then achieve the ultimate goal of rapid heat transfer. First, during a certain heating time period, the hot air flow will continue to enter the heat storage body in the regenerative heat exchanger, so that the thermal energy is transferred in the hot fluid, that is, the transfer direction is inside the heat storage body, so This results in a drop in the temperature of the hot fluid itself. After the end of the cycle, the cold fluid passes through the interior of the heat storage body, and the fluid will absorb a large amount of heat in the heat storage filler. During this process, the temperature in various parts of the heat storage body and the fluid will fluctuate continuously over time and change. After the system is started, it must be switched continuously through the relative cycle. At this time, the regenerative heat exchanger can be in a stable operation state to ensure the stable and continuous rate of heat absorption and release of various parts of the heat storage body. .

Direct contact heat exchanger, also called "hybrid heat exchanger". It is mainly based on the contact and collision of two fluids with different phases to form a mixed heat exchange method [3]. And then play the ultimate heat exchange purpose. After analysis, it is found that the direct contact heat exchanger has an optimized function to a certain extent, avoiding the thermal resistance caused by the formation of dirt on the heat transfer partition and on both sides of the traditional heat exchange. Maintaining good contact performance between fluids will quickly increase their heat transfer rate. Therefore, as long as the conditions that the fluids can be mixed with each other can be met, hybrid heat exchangers can be adopted.

Scan the QR code to read on your phone

Recommend news

Business Center:Room 806, Building 10, Pomefranate Center, No.88, liuxiang Road, Fengtai District, Beijing

Factory Address:NO.600, Chuangye Road, Economic & Technologiy Development Zone, Langfang, China

Service tel:+86-10-85387400

BEIJING AMAX Heat TRANSFER Equipment ManufactURE Co., Ltd. 京ICP备10048098号-1 www.300.cn