Details

The role and application of heat exchanger in chemical process production

- Categories:Industry information

- Author:

- Origin:

- Time of issue:2021-11-05 09:08

- Views:

(Summary description)The most typical role of the heat exchanger in the application process is to achieve heat conduction control and ensure the uniformity of heat transfer. As far as the function of the equipment is concerned, in most cases, the individual with more heat produced by the product is transferred to the lower individual, so as to maintain the control stability of the production process and the uniformity of heat.

The role and application of heat exchanger in chemical process production

(Summary description)The most typical role of the heat exchanger in the application process is to achieve heat conduction control and ensure the uniformity of heat transfer. As far as the function of the equipment is concerned, in most cases, the individual with more heat produced by the product is transferred to the lower individual, so as to maintain the control stability of the production process and the uniformity of heat.

- Categories:Industry information

- Author:

- Origin:

- Time of issue:2021-11-05 09:08

- Views:

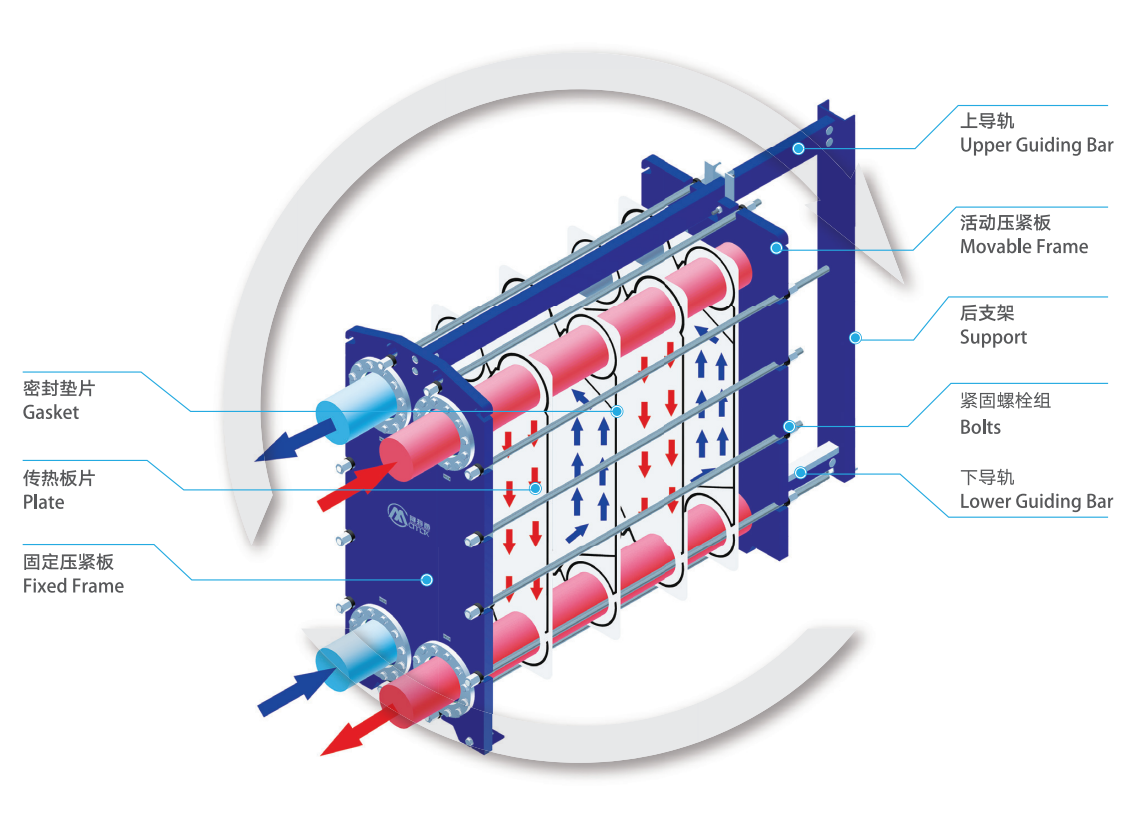

The most typical role of the heat exchanger in the application process is to achieve heat conduction control and ensure the uniformity of heat transfer. As far as the function of the equipment is concerned, in most cases, the individual with more heat produced by the product is transferred to the lower individual, so as to maintain the control stability of the production process and the uniformity of heat. When selecting some equipment with larger heat transfer, it is necessary to consider the requirements of the heat transfer area to ensure the effect of chemical operations. Compared with other types of heat exchangers, the plate heat exchanger has more advantages. When selecting a heat exchanger, it should be gradually realized in accordance with the requirements of design standards and efficiency.

Through the heat exchanger, the relationship between temperature and pressure can be adjusted to better meet the needs of industrial production. For example, in a chemical production environment, with the help of plate-fin heat exchangers, continuous heat exchange operations in a higher temperature environment can be achieved and a constant temperature can be maintained. After comparing various heat exchangers, we can find that when the temperature and pressure conditions are stable, the temperature and pressure can reach the corresponding standards. The tube heat exchanger itself has the characteristics of low production difficulty and high price advantage, so it has an irreplaceable role in the production of chemical processes. Adjusting the temperature and pressure relationship through the heat exchanger can improve the stability of the process, and also help to improve the production relationship and enhance the comprehensive benefits of the enterprise.

The problem of large-area heat transfer is an important problem that plagues chemical production. Shell and tube heat exchangers and plate heat exchangers, different types of heat exchangers have different heat transfer requirements for the heat area. When the area of the heat exchanger is low, you can choose a plate heat exchanger with an air cooler. However, because the cold area of the air has certain advantages in a high-temperature environment, the air cooler is the dominant one, while the heat exchanger As auxiliary equipment. However, in the actual application process, the air cooling equipment is prone to be affected by the external temperature. Therefore, in the actual application process, it is necessary to consider the actual needs and apply it after comprehensive analysis to ensure that the chemical production work can be carried out smoothly.

The gas phase and liquid phase exchange mode is a link that often needs to be involved in chemical production. In addition to removing the conventional heat transfer control requirements, the heat exchanger also needs to combine temperature, pressure and other conditions to control the heat transfer function during the application process. The exchange of gas and liquid phases in this process obviously also requires heat control. According to the actual functions of the liquid phase and the gas phase, the heat exchanger is selected and the appropriate parameters are adjusted to continuously meet the control requirements of the production quality and also help to promote the realization of the production function. In addition, in the process of realization, it can meet the adjustment requirements of the exchange mode of liquid and gas, so energy consumption can be reduced, good economic and social benefits can be obtained, and the practical effect of heat exchanger application can be improved.

In summary, heat exchangers play an irreplaceable role in chemical production. By analyzing the concept of heat exchangers, we can further understand the role of heat exchangers in chemical production. In fact, different types of heat exchangers have many similar design features, but they have many differences and design differences for different fields. By optimizing the function of the heat exchanger, the role of the heat exchanger in chemical production can be effectively improved, meeting the requirements of heat transfer control, solving the problem of temperature and pressure control coordination, solving the problem of large-area heat transfer, so as to meet the requirements of production. Achieve good economic and social benefits.

Scan the QR code to read on your phone

Recommend news

Business Center:Room 806, Building 10, Pomefranate Center, No.88, liuxiang Road, Fengtai District, Beijing

Factory Address:NO.600, Chuangye Road, Economic & Technologiy Development Zone, Langfang, China

Service tel:+86-10-85387400

BEIJING AMAX Heat TRANSFER Equipment ManufactURE Co., Ltd. 京ICP备10048098号-1 www.300.cn